There are multiple probes (as few as 4 and as many as 20 needles) that can take measurement simultaneously of different parameters (voltage, current, resistance and continuity) between any two points on the PCB. The component orientation and component polarity detection is done by a high definition camera installed on the PCB flying probe setup. The testing system is pre-programmed to carry out different measurements like voltage, current measurement, and impedance measurement, components value like resistance, capacitance and inductance. The robotic arm end effector is actually the probe that is connected to the back end testing system. The flying probe test (FPT) is basically the system of automated robotic hands that can move in x, y coordinates to gain access to each and every point on entire PCB and use z axis to move the probe vertically towards and away from the PCB. The PCB is moved on the conveyer belt and brought directly under the robotic architecture of flying mechanism of testing system. The flying probe test also called “Fixtureless Testing” on the other hand do not have a bed of nails fixture except it has a fixture to simply hold the bare or assembled PCB board. Request F lying Probe Test Service Why to use Flying Probe Test (FPT): The ICT testing can access most of the nodes of the PCB to test and measure but some nodes that are hidden/shielded or under a larger component so these nodes remain untested and hence confidence will be less that the board still have some faults located in nodes that remained unreached due to incapacity of nails/ICT fixture. This is because the initial design and development cost of ICT fixture is very high and the design fixture is different for different PCB designs. The ICT testing is suitable large run or mass production of a particular PCB. The measurements like resistance, inductance and capacitance between two points in the PCB can be done using ICT.

CIRCUIT BOARD TEST POINTS DRIVERS

The in circuit tester is the matrix or array of sensors and drivers setup to perform measurement. The ICT is also called the Bed of Nails test because the fixture is actually the nails or points that go directly in the circuit board. The fixture is the interface between the circuit tester and the PCB. But once the fixture is made it can be attached to the in-circuit test system to simply perform the ICT within few minutes. This fixture is different for every different PCB design and hence the CEM has to develop this fixture and it take a lot of time in development of fixture. ICT has its own advantages while FPT has its own, it depends upon the user requirement how the user want the PCB to be tested and what budget constraints of user are.Īctually the ICT testing requires a solid “fixture” that the CEM will develop to access the test point in the circuit / PCB. There are strength and weaknesses of each of the two electrical PCB testing methods for PCBs.

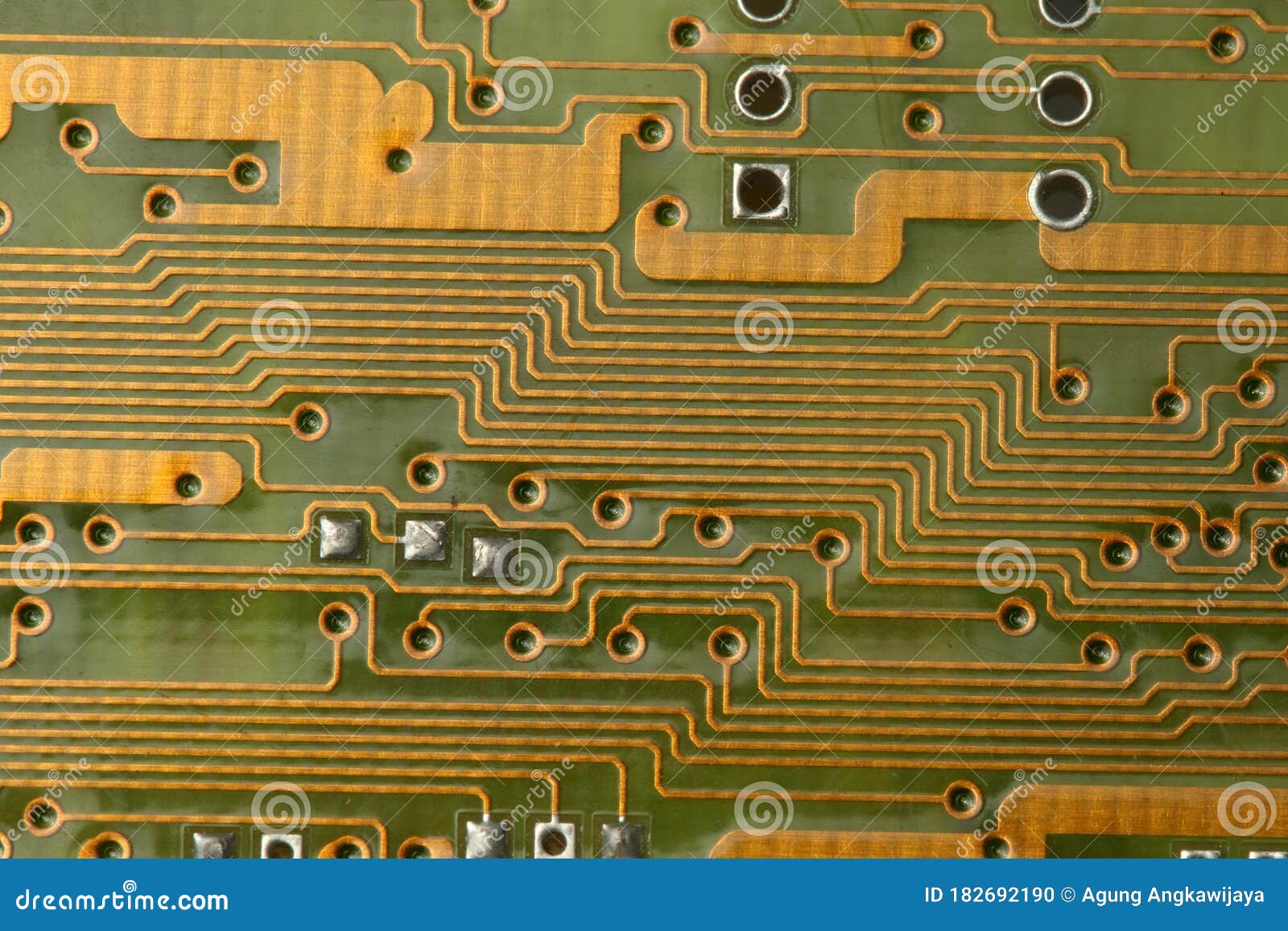

Request F lying Probe Test Service ICT vs FPT There are various types of electrical parameters like short circuit, open circuit, voltage, current, resistance and capacitance etc. These electrical test ensures that the bare PCBs or stuffed PCBs that leave the factory are comprehensively tested in the domain of electrical parameters. These tests are also called “Electrical Performance Test”. These tests are 1- In Circuit Test 2- Bed of Nails Test 3- Flying probe test. To check this, there are various tests that are performed by PCB manufactures or Contract Electronics Manufacturers (CEM) also called Electronic manufacturing Supplier (EMS). However it is utmost important that the PCB itself and the components residing on the PCB are not faulty and are not defected and connected correctly. The components along with PCB copper tracks are connected with each other and designed to carry out one or more than one functions. These PCBs are fully loaded with electronic components like resistors, capacitors, ICs, inductors, transformers, chokes, jumpers and connectors and many other stuff. These PCBs are consisted of the hard green color board commonly seen in all electronic equipment when it is opened inside. We all are familiar with Printed Circuit Boards (PCBs) to be the core of electronic products functionality.

0 kommentar(er)

0 kommentar(er)